Softwood

Softwood in not always a softer material than hardwood and a Hardwood is not always harder or denser than a softwood. Timber species and qualities vary dramatically and in botanical terms they are categorised as angiosperm or gymnosperms.

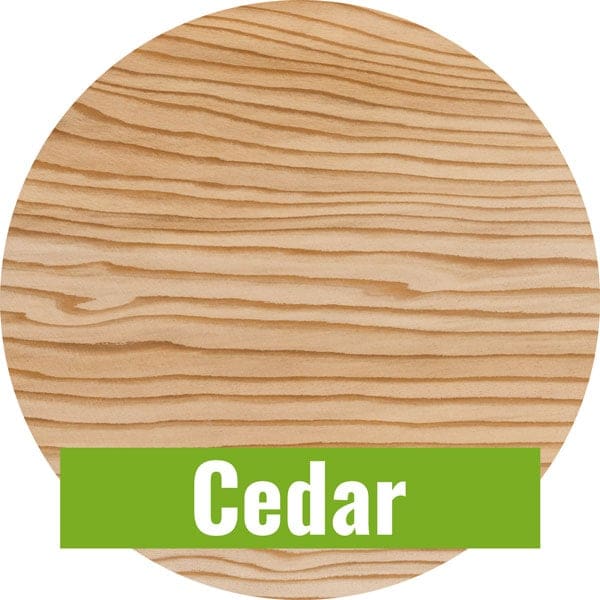

Softwood trees are fast growing gymnosperms and reproduce from cones, usually keeping their foliage all year round such as evergreens like, Thermowood, Douglas Fir, Larch and Cedar.

ThermoWood is a modified wood (either whitewood or redwood) made by heat treating softwood in a kiln at a high temperature. The heat dries out any moisture and resin. Reducing the moisture content of approximately 8-10% and enhancing a product that is 50% more stable than untreated softwood.

This process makes the product very stable and offers a high resistance to decay and fungal attack. This product is ideal for external cladding of Bin stores, with no need for additional treatment. However, it can be easily stained, just as any other softwood.