Metals

At Bollard Street, we are not just manufacturers; we are innovators in crafting exceptional metal street furniture that stands the test of time and elements. Our expertise lies in harnessing the strength and versatility of a variety of high-quality metals, each carefully selected for its unique properties and environmental sustainability.

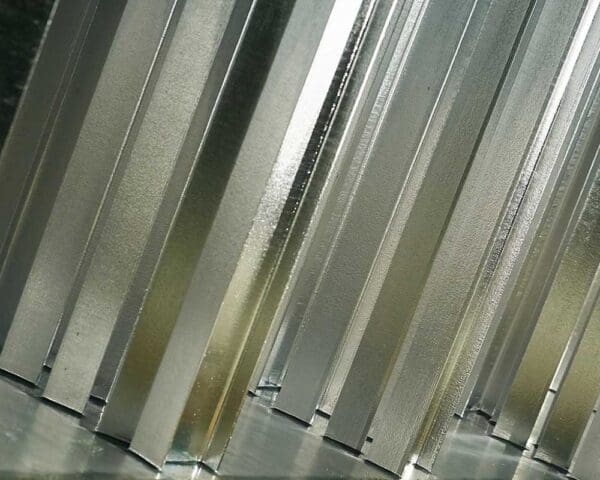

Our range includes the sleek and robust stainless steel, known for its corrosion resistance and sleek finish, ideal for both modern urban landscapes and traditional settings. We also utilize mild steel, valued for its durability and flexibility, making it a perfect choice for heavy-duty applications. For those looking for something a little more unique, our use of Corten steel adds an artistic touch with its distinctive rust-like appearance that naturally weathers over time, offering an aesthetically pleasing, maintenance-free option for outdoor spaces.

Our commitment to sustainability and durability is at the forefront of our design philosophy, ensuring that each piece of metal street furniture we create not only enhances the visual appeal of public spaces but also contributes positively to the environment.

Take a look at our full product range to find the perfect street furniture for your needs, or contact us today to find out more about how we can help you to fulfill your vision.